Machine vision might sound like a concept pulled straight from science fiction, but it's an essential tool in today's manufacturing world. It's the technology that allows machines to "see" and analyze their environment through advanced imaging systems. For example, in semiconductor production, it ensures every chip meets exacting standards by detecting microscopic defects that human eyes could miss. Without this precision, manufacturing flaws could lead to costly recalls or failures in consumer devices.

From identifying microscopic scratches on a smartphone surface to ensuring precision in semiconductor production, machine vision ensures accuracy and consistency at a scale humans could never achieve.

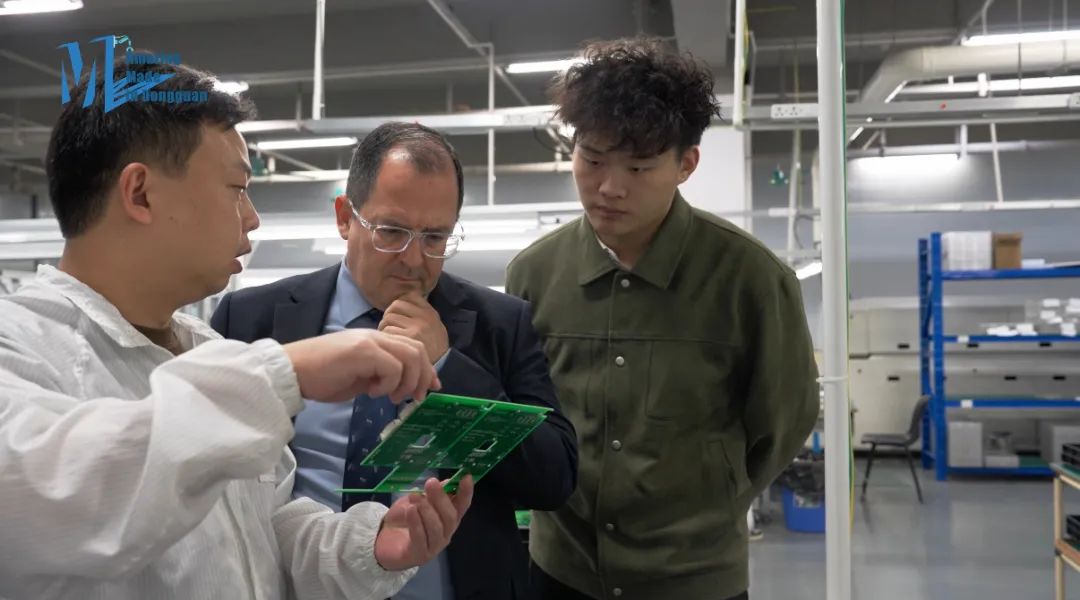

Recently, Colombian blogger Fernando, playing the role of a corporate executive, ventured to Dongguan to uncover the secrets behind this technology. His destination, CST Machine Vision Co. Ltd., a company that has become a leader in machine vision solutions.

CST, founded in 2007, emerged during a time when China's machine vision industry was just beginning to grow. Over the past 15 years, it has become one of the pioneers in the field, offering comprehensive solutions for industries ranging from electronics and robotics to medicine and automotive. With a robust team of experts and a database of over 30,000 case studies, CST has made solving imaging challenges its mission.

Within CST's state-of-the-art optical lab, Fernando witnessed the system at work. A phone screen was placed under the scanner, and within seconds, an ultra-clear image appeared on the screen, revealing microscopic flaws invisible to the naked eye. "Wow! That's exactly amazing," Fernando gasped.

"It can detect defects, measure dimensions, identify colors, inspect QR codes, and more," an engineer of CST explained proudly.

What sets CST apart isn't just its technical expertise but also its commitment to excellence. As he toured CST's production floor, Fernando saw automated systems working seamlessly alongside stringent quality controls, while its automated logistics ensure timely deliveries. With a sample customization cycle of less than three days, CST responds swiftly to customer needs, providing a competitive edge in fast-paced markets.

Impressed by CST's dedication, Fernando remarked,"You're not just building machines; you're shaping the future of AI-driven manufacturing. With this level of precision, I'll never have to worry about product quality again!"

Dongguan's advantage as a hub for machine vision technology lies in its unparalleled manufacturing ecosystem. The city boasts a robust industrial base, skilled talent pool, and a thriving spirit of innovation. Companies like CST exemplify this synergy, pushing the boundaries of what's possible and positioning Dongguan as a global leader in intelligent manufacturing.

Fernando summed up his visit with enthusiasm: "Dongguan has truly impressed me. I'll make sure more people know about this incredible city!" He was astonished not just by the technology but by the seamless integration of expertise, innovation, and culture in Dongguan. As the global demand for precision manufacturing grows, it's clear that Dongguan, with companies like CST at its forefront, will play a pivotal role in shaping the future of machine vision.