In a swift turn of events, the recent tariff reduction between China and the United States has injected fresh momentum into global trade. Nowhere is this shift more palpable than in Dongguan, one of China's key export-oriented cities. From manufacturers to logistics providers, local businesses are moving quickly to fulfill backlogged U.S. orders and seize new global opportunities.

Within 48 hours of the joint statement released in Geneva and the mutual tariff cuts on May 14, container bookings from China to the U.S. surged nearly 300%, according to data from logistics tracking platform Vizion. In Dongguan, factories that had been idling due to trade uncertainties are suddenly bustling again.

At Guangdong Aesonic Technology Co., which specializes in audio products with a third of its business coming from the U.S., Chairman Deng Wenwu described the atmosphere as "everyone returning to work after a long break." U.S. clients flooded him with inquiries, eager to push out delayed shipments that had piled up in warehouses for months.

But Dongguan's response goes far beyond short-term recovery. The city's export-oriented firms have used recent years of global headwinds to rethink and strengthen their strategies. "We've already shifted part of our manufacturing to Vietnam, but the core supply chain remains in China. It's still more competitive here," said Zheng Xingzhong, general manager of Dongguan Guanrui Furniture, who is now eyeing markets in the Middle East and North America beyond the U.S.

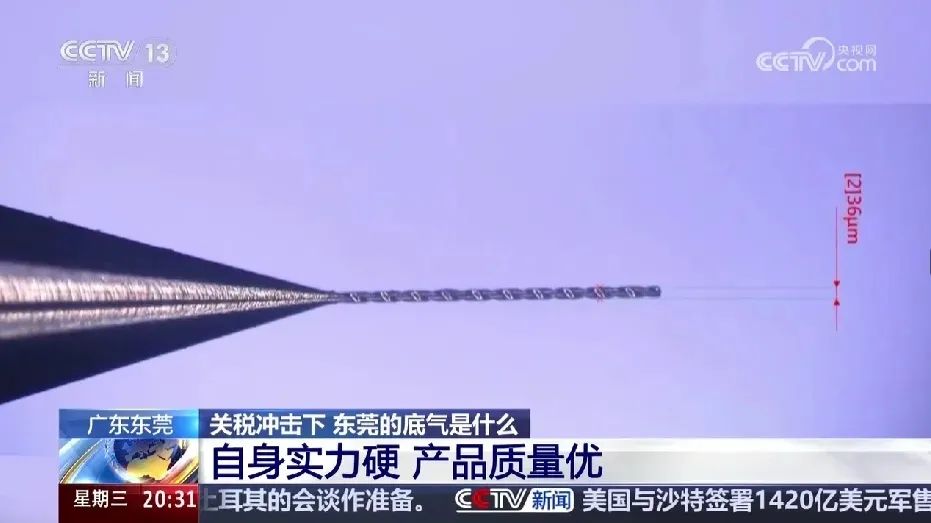

This kind of flexibility is shared across industries. Tech-driven manufacturers are gaining a clear edge. PCB toolmaker DTECH, whose micro-drilling bits are thinner than a human hair, leads global sales through self-developed equipment and consistent R&D. "Whatever changes come internationally, we're confident in our core technologies," said R&D Vice Director Lin Haisheng.

The city's edge isn't just about individual innovation, it lies in Dongguan's full industrial chain. In Houjie Town, the 5-kilometer "Furniture Avenue" is home to over 2,000 companies. Here, it's said a piece of fabric can become a sofa after crossing just three traffic lights. Such hyper-efficient supply chains allow rapid customization and delivery for global orders.

Chen Xuhui, manager at Changshi Furniture, noted that most suppliers are within a 5 km radius, materials can arrive the same day, and hardware parts within an hour. With over 80% of their products exported to 61 countries, responsiveness has become a core competitive strength.

Dongguan's manufacturing upgrade is also underway. Companies like Topstar Technology are building customizable automated lines for clients, transforming "Made in Dongguan" into "Smart Manufacturing in Dongguan."

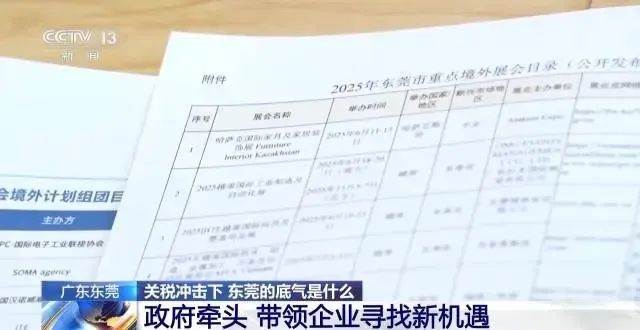

Despite global uncertainties, Dongguan's export engine continues to run on innovation, complete supply networks, and a pragmatic approach to market diversification. With government support for overseas exhibitions and cost subsidies, more firms are exploring new markets, from Europe to Southeast Asia and South America.

The U.S.-China tariff thaw may be temporary, but Dongguan is clearly playing the long game, one built on resilience, speed, and a global mindset.