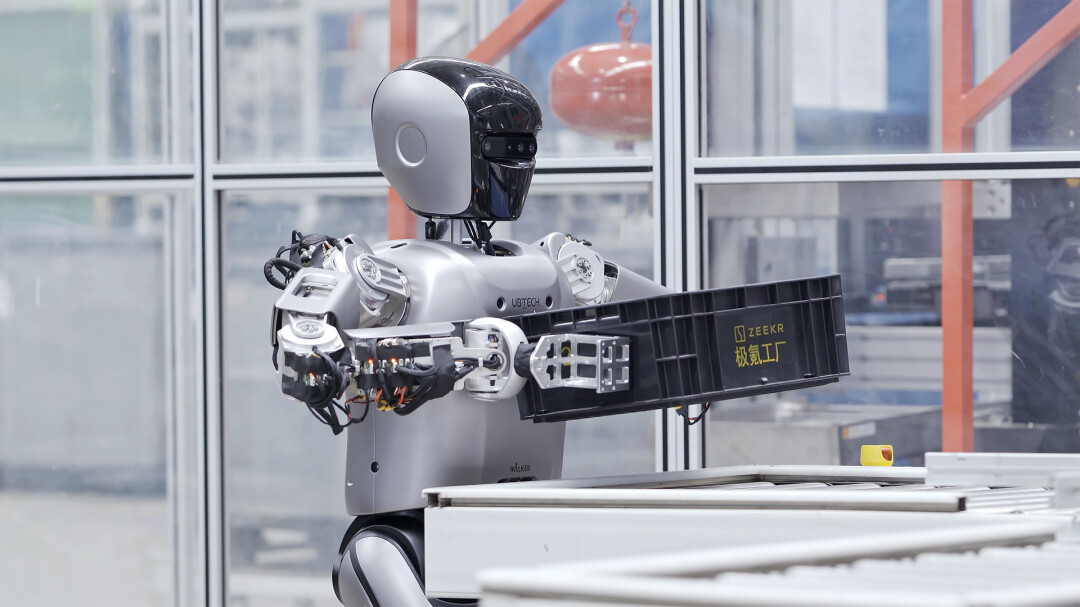

This summer, Walker S Lite, an industrial humanoid robot from Shenzhen-based UBTECH Robotics, has joined Geely Holding Group's Zeekr 5G Smart Factory, becoming the facility's first humanoid robotic "employee."

(Photo: Nanfang Daily)

Walker S Lite marks the first time in China that a humanoid robot has fully executed and demonstrated material handling tasks from start to finish. As UBTECH's latest lightweight and rapidly deployable product tailored for smart manufacturing and intelligent logistics, Walker S Lite has undergone 21 consecutive days of "training" at the Zeekr 5G Smart Factory. Its duties involve collaborating with human workers at the CTU (Container Transport Unit) inbound loading station to perform lifting and transportation tasks, achieving an industry-leading level of completion and difficulty.

Recently, UBTECH, Geely, and Tianqi Automation have forged a strategic partnership. Leveraging their respective strengths, the trio aims to jointly advance the application of humanoid robots in the automotive and auto parts smart manufacturing sectors, creating innovative demonstration projects.

(Photo: Nanfang Daily)

UBTECH will utilize its cutting-edge AI and humanoid robot technology to support Geely's electric and intelligent transformation. Geely, in turn, will provide application scenarios for UBTECH's industrial humanoid robot Walker S series and solutions, enhancing the quality and efficiency of smart manufacturing. Meanwhile, Tianqi Automation will leverage its engineering expertise to contribute to the data collection, process model development, and scenario improvement design for humanoid robot training. Looking ahead, the three partners are committed to driving the large-scale deployment of humanoid robots tailored for smart automotive and auto parts manufacturing scenarios.

During its three-week "training" period, Walker S Lite demonstrated its capabilities in autonomous navigation and load-bearing mobility across different pallets and assembly lines. Integrating semantic VSLAM (Visual Simultaneous Localization and Mapping) navigation, end-to-end imitation learning, precise visual recognition, and refined full-body motion control, it collaborated seamlessly with AGVs (Automated Guided Vehicles) to accomplish tasks.

Notably, tailored for smart manufacturing and logistics applications, UBTECH's newly developed anthropomorphic arm utilizes advanced structural lightening techniques such as topology and size optimization. Equipped with high-performance servo drives and six-axis force sensors, Walker S Lite can stably carry boxes weighing up to 15kg, making it suitable for a wide range of industrial and logistical transportation tasks. Material handling is ubiquitous in smart manufacturing and logistics, and Walker S Lite's reliable performance underscores the vast potential and deployment capabilities of UBTECH's industrial humanoid robots. By equipping various end-effectors, Walker S Lite can undertake tasks such as object handling, quality inspection, SPS sorting, chemical handling, and assembly.

(Photo: Nanfang Daily)

Xu Jun, head of the Innovation Technology Department at Geely's ME Center, emphasized that advanced manufacturing's core objectives are to enhance product quality, reduce production costs, and boost efficiency. To meet growing personalized demands, the manufacturing sector is transitioning from high automation to full intelligence. AI-powered humanoid robots, with their multimodal perception and autonomous decision-making capabilities, offer significant advantages in complex and dynamic work environments, holding immense potential in smart manufacturing.

Jiao Jichao, Vice President and Executive Dean of UBTECH's Research Institute believes that deploying humanoid robots in real automotive manufacturing environments enables the continuous accumulation of comprehensive production data. Leveraging AI for perception, learning, and iteration, a closed-loop intelligent management system can be achieved. With embodied intelligence and autonomous learning capabilities, humanoid robots can swiftly adapt to new tasks, facilitating agile deployment in manufacturing scenarios and contributing to high-quality, agile product delivery.

Guo Dahong, Director of Tianqi Automation's National Technology Center, stated that Tianqi, with years of experience in automotive production line smart equipment, possesses advanced technologies ranging from high-end intelligence to efficient human-robot collaboration. The trio's collaboration aims to explore humanoid robots' ability to interact with equipment, personnel, and environments in discrete manufacturing factories, supporting flexible and customized production lines with comprehensive smart technology solutions.

(Photo: Nanfang Daily)

Since the beginning of this year, UBTECH has focused on key manufacturing sectors like automotive and 3C, enhancing its humanoid robots' tool manipulation and task execution capabilities. Globally, UBTECH has pioneered partnerships with multiple automakers, with its robots undergoing practical training in their factories.

Early in 2024, Walker S, another industrial humanoid robot from UBTECH, entered NIO's second advanced manufacturing base for on-site "training." Subsequently, Dongfeng Liuzhou Motor, FAW-VW Automotive Co. Ltd Qingdao Branch, and Geely Auto have also collaborated with UBTECH to create demonstration production lines and factories.

Author | Alice

Editor | Monica, James