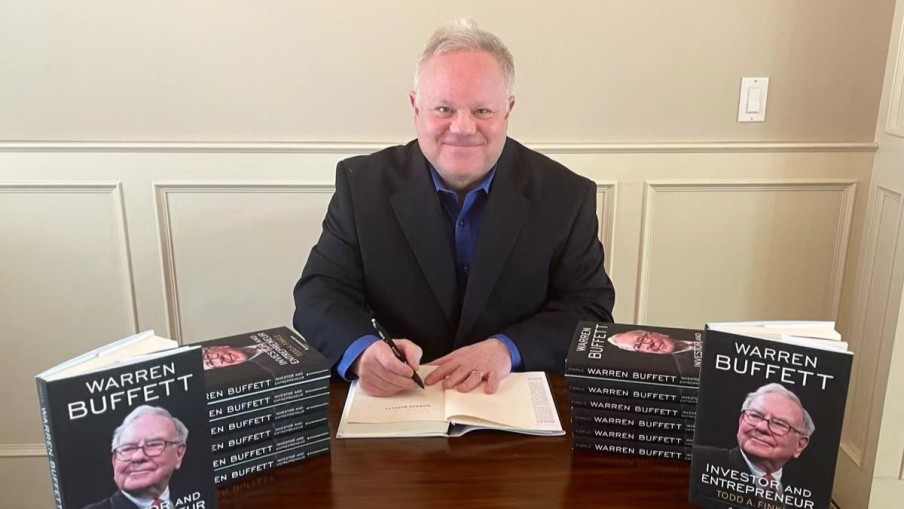

Wall Street Frontline|Todd Finkle on What to Expect from Warren Buffett's Annual Meeting 2024

In the ever-evolving world of finance and investment, few figures stand as prominently as Warren Buffett. With the 2024 Berkshire Hathaway Annual Meeting on the horizon, we invited Professor Todd Tinkle, the author of "WARREN BUFFETT: INVESTOR AND ENTREPRENEUR", to share his thoughts on the possible themes and announcements in this year's annual meeting.